© Copyright 2011 Julianne Dodds

Timber, Veneer and Plywood

1901 - 1969

From country to city

Kingston Glue Factory

The greatest expenses in running a timber mill were wages and logs. The ‘milk’ was needed to make the

casein glue to glue sheets of veneer together to make the plywood.

In the beginning, 200 to 1000 gallons of

skim milk per day were required.

In October 1918 Mac purchased

12 ½ acres of land at Kingston, south

of Brisbane beside the railway line.

He built a glue factory and, using the

buttermilk from the nearby Kingston

Butter factory, produced his own casein

glue.

Glue Factory built at Kingston, south of Brisbane in 1918.

Williams Collection.

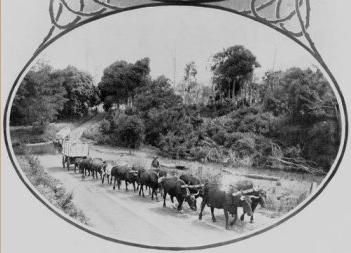

Bullock team hauling logs in the Canungra district.

John Oxley Library, State Library of Queensland.

Image number: 170790

The bullock teams

Mac had been purchasing his pine logs

from the Beechmont Pine Company near

Canungra. To cut expenses he decided

to fell and mill his own timber. In 1918

he bought a property at Josephville,

nine miles south of Beaudesert that was

covered with 6,000,000 feet of standing

pine. Timber-getters worked with double-

handed saws cutting down the pine trees.

Stripped of excess branches the trees

were loaded onto a wagon. A team of

bullocks was yoked to the wagon and

slowly made its way along the dusty road

to the sawmill. The logs were either sawn

into planks or taken down to the railway

siding and railed to Coorparoo.